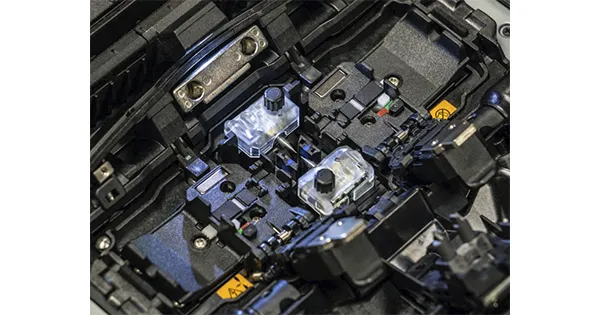

Fujikura Core Alignment Fusion Splicer 90S

The 90S is a core alignment fusion splicer setting a new standard in the market for fusion splicing. The 90S is packed with a whole host of new and enhanced features specifically developed with the objective of enabling the user to work faster with higher precision. Overall splice process time has been significantly reduced. This has been achieved with a combination of improvements to the reaction time of the automated wind protectors and automated heater, new fibre retention clamps, improved universal sheath clamps and a redesigned internal structure that matches the protection sleeve to the fusion splice point which enables splicing to be achieved without the need of the user to touch the 90S once the process has started.

Features

• Market leading high precision and accurate core alignment technology with advanced image processing.

• Improved automatic wind protector design which reduces overall splice time but can also be used manually.

• Patented easy splice protector positioning system.

• Fibre Retention clamps.

• Universal sheath clamps for standard 250 um fibre as well as 900 um loose tube fibre types.

• A completely redesigned multi-function carry case and workstation.

• Enabled with Fujikura’s unique “Active Blade Management Technology” with new capability to link up to two CT50 cleavers simultaneously.

• Tool-less replaceable electrodes.

• High capacity lithium-ion battery (up to 300 splices).

• Touch screen.